The automotive industry has gone through many incredible innovations throughout recent years, and a lot of these innovations are closely related to eco-friendly targets like fuel efficiency, hybrid designs, electric cars and sustainable engineering.

One eco-friendly aspect of the auto industry that doesn’t get talked about too much is auto leak testing, and this type of leak testing is actually incredibly important for automotive OEMs (original equipment manufacturers) for all sorts of safety, efficiency and reliability purposes.

The Daily Magazine team has partnered up with the auto leak testing salt lake city ut experts at Z-Axis to provide our readers with a comprehensive overview about auto leak testing. So, check out the below sections to learn more about the common types of auto leak testing!

Understanding Your Auto Leak Testing Applications

Automotive OEMs first need to thoroughly understand their leak testing applications while they’re preparing arrangements with leak testing experts.

There’s a lot that you’ll need to narrow down during these complex discussions, including:

- Physical parameters: This means understanding the internal volume of the application or component that’s being leak tested. You’ll also need to know factors like test pressure readings and flow rate specifications. You also need to understand what materials the auto component is comprised of, as well as how much flexibility the materials have.

- Auto device functionality: It’s also crucial to provide auto leak testing specialists with detailed information about how a specific auto device functions within a vehicle.

- The device’s functional environment: Auto leak testing experts also need to understand how specific devices are stored or controlled within a vehicle. Some examples include a pressurized space or other types of controlled environments.

- Auto leak testing environment: Auto leak testing environment is also an important factor for automotive OEMs to keep in mind, because cleanliness can often have an impact on how leak testing enclosures are decided.

- Manufacturing Stage: This essentially means that you should know when your leak testing will take place within the broader scope of your manufacturing processes.

- Production targets: Everyone has different leak targets that need to be met, so it’s important to understand how much your auto components can leak while still passing the leak test.

Test Part Inspections

Auto leak testing is a very complex procedure, which is why most OEMs will send leak testing experts a test part prior to the actual testing. It’s also common for leak testing specialists to conduct visual inspections long before they actually test for leaks.

Most automotive designs and components require on-site inspections, but these days a lot of people will do video calls as well to save time and resources. The main purpose of these inspections is to better prepare your leak testers for what they’ll ultimately provide in the long run.

Auto Leak Testing Configuration Capabilities

It’s also important to understand how there’s a wide variety when it comes to test steps and I/O sophistication within the auto leak testing industry. If flexibility is important for your leak testing, there are specific designs and products that accommodate these needs.

Auto leak testing equipment also comes in a variety of different data communication options, so there are many more subtle decisions that automotive OEMs need to keep in mind while they’re testing their products.

Best Leak Testing Products For Automotive OEMs

There’s no denying just how important air leak testing is for automotive OEMs, because this is a crucial quality control step that helps companies avoid all sorts of different catastrophic results. Some common issues that leak testing helps automotive OEMs avoid include:

- Compromised performance

- Decreased fuel efficiency

- Increased emissions

- System shutdowns

- And much more!

These potential issues are just a tiny glimpse into why air leak testing is so important for automotive manufacturers, and OEMs need to invest in top-quality leak testing solutions in order to guarantee the quality of their products and services.

Some of the most reputable air leak testers that support the automotive industry include:

- Isaac HD Modular Air Leak Tester

- 7i Air Leak Tester

- PD Pressure Decay Air Leak Tester

- iKit Automated Air Leak Tester

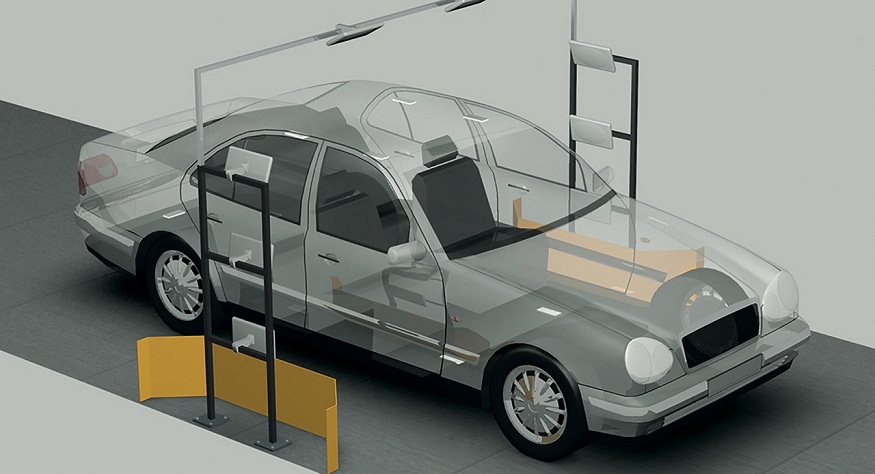

Automotive Components That Need Leak Testing Solutions

There are many different common automotive components that require comprehensive air leak testing solutions, including:

- Fuel injectors

- Fuel tanks

- Cylinder heads

- Intake manifolds

- Exhaust manifolds

- Engine blocks

- Powertrains

- EV batteries

- Electrical components

- Airbag assemblies

- And A LOT more!

Choosing The Correct Leak Testing For Your Automotive Business

It’s also important for automotive OEMs to understand just how many different air leak testing methods there are within the automotive manufacturing industry. The most common include:

- Pressurized decay testing: This includes the auto component being pressurized with gas, and this pressure is then monitored and evaluated for decay—which indicates potential leaks.

- Vacuum decay testing: This leak testing method requires the auto component to be fully evacuated, and the vacuum is then monitored for leak decay.

- Mass flow testing: This includes a gas flow rate being measured as the gas flows through the auto component. Any deviations from an expected flow rate will indicate a leak that needs attention.

Reach Out to Z-Axis When You Need Auto Leak Testing in the Salt Lake City UT Area!

There’s a lot that automotive manufacturers and OEMs need to consider when it comes to air leak testing, and the above factors are just a tiny glimpse into this incredibly complicated industry.

One of the auto leak testing industry leaders is Z-Axis, which is a revolutionary business based in Salt Lake City, UT. You can speak directly with the Z-Axis team about their auto leak testing services when you check out the link to their website at the top of this article!